1700mm PP twin wall sheet making machine: it is used for making PP hollow sheet which is used for making Plastic Packing box

PC/PE/PP Hollow Grid Plate Extrusion Line, PP hollow sheet making machine, PP twin wall sheet making machine, PP packing box production line, PP corrugated sheet extrusion line.

This PP twin wall sheet making machine realizes continuous production of PC/PE/PP hollow grid plate, which is applicable to construction decoration, advertisement collocation, and noise insulation of highway as well as packaging. PE/PP hollow grid plate is an ideal substitute for paper box in making packaging box. It is characterized by light weight, high intensity, dam-proof, and anti corrosion. The width of the products is 1220-2100 mm, and the thickness is 2 mm-12 mm.

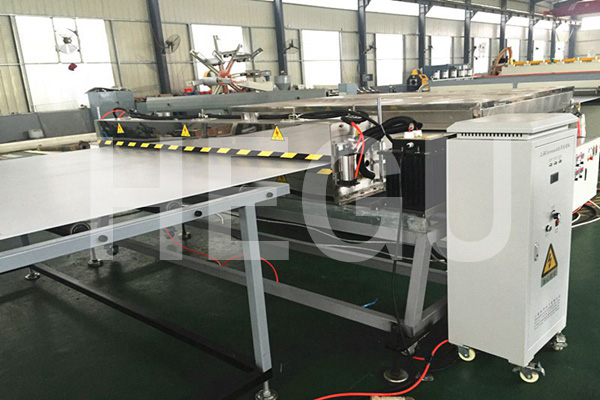

Machine pictures for PP twin wall sheet making machine:

1,Material mixing silo for PP twin wall sheet making machine: it is used for mixing PP material with filling masterbatch and color masterbatch

2, Extruder for PP twin wall sheet making machine: The specially designed screw and the advanced controlling system ensure excellent palatalization, high output and stable extruding.

if customer want to use recyle material, we also can equip co-extrusion line for making double layer PP hollow sheet, inner layer can use recycled PP material, and upper layer can use new PP material.

3, die head and mold for PP twin wall sheet making machine: we can equip the die head and calibrator for different width, such as 1220mm, 1700mm, 2100mm,2300mm,2500mm

Screen changer for PP twin wall sheet making machine: Quick screen changer of hydraulic system ensures the short course of screen changing. Double-position combined with special sealing structure guarantee stable operation of screen changer.

Mould: Mould adopts high-quality alloy steel and throttling device to ensure even pressure of feed influent at the mould lips, and also differential action of up-down piece guarantee even thickness of the plate.

Vacuum calibrating table for PP twin wall sheet making machine: Heating exchanging and cooling system of quick speed in calibrating system alternate effectively and ordinarily with vacuum system, which ensures calibrating precision. Vacuum system composes two independent subsystems and each is equipped with several fixed circulating vacuum lines of three-point type. Meanwhile, each line carries vacuum regulating system and vacuum display system that realize even and stable vacuum degree of plate surface.

Tractor for PP twin wall sheet making machine: There are two tractors. The first one is high power, high reduction ratio, multi-roller type, well low-speed operation, high traction and is able to draw the plate up from the calibrating table evenly and synchronous. The second one is designed to remove stress, and in addition it is equipped with edge-cutting device to ensure the valid width and smooth cut of the edges.

Stress remover for PP twin wall sheet making machine:The advanced large area conductive heating mode can effectively remove the stress of plate and further improve plainness of the plate.

Cutting machine for PP twin wall sheet making machine: Accurate instant length-fixed cutting and automatic up-down discharging system combined with alloy steel sharp blade realize high quality of cutting.

Final product and application made by PP twin wall sheet making machine

1, WARRANTY TERMS:

1.1 WARRANTY PERIOD: 12 MONTHS, STARTING FROM THE FIRST DAY OF RUNNING MACHINES IN CUSTOMER’S WAREHOUSE

1.2 SELLER SHALL GRANT: SERVICES AND SPARE PARTS, FREE-OF-CHARGE SERVICE THROUGHOUT THE ENTIRE EQUIPMENT WARRANTY PERIOD.

1.3 LIFELONG SERVICE: THE SELLER SHOULD PROVIDE LIFELONG SERVICE FOR THE SOLD GOODS, THE BUYER PAY FOR NEEDED SPARE PARTS AFTER THE 12MONTHS WARRANTY TERMS.

2, DELIVERY CONDITIONS:

2.1 DELIVERY CONDITION: FOB QINGDAO PORT.

2.2 DELIVERY TERM: WITHIN 60 WORKING DAYS AFTER RECEIPT OF ADVANCED PAYMENT, THE SELLER SHOULD INFORM THE BUYER TO DO INSPECTION. THE SELLER SHOULD FINISH PACKING OF GOODS AND READY FOR SHIPMENT WITHIN 15 WORKING DAYS AFTER THE SELLER RECEIPT THE FULL PAYMENT.

2.3 SUPERVISION OF LOADING:THE SELLER SHOULD INFORM THE BUYER EXACTLING LOADING TIME, THE BUYER CAN ARRANGE FOR SUPERVISION OF LOADING.

3, INSPECTION:

WHEN THE MACHINE FINISHED, THE SELLER SHOULD INFORM THE BUYER TO DO INSPECTION BEFORE SHIPMENT, THE SELLER GUARANTY GOOD PERFORMANCE OF ALL THE SOLD GOODS.THE SELLER UNDERTAKE THE MATERIAL COST FOR THE MACHINE INSPECTION IN SELLER’S FACTORY. THE BUYER SHOULD COME TO SELLER’S FACTORY TO DO THE INSPECTION WORK, OR THE BUYER COULD ENTRUST ANY THIRD PARTT TO COME TO SELLER’S FACTORY TO DO THE INSPECTION WORK.

4, INSTALLATION AND EQUIPMENT COMMISSIONING:

IF THE BUYER REQUIRES, THE SELLER SHOULD SEND TECHNICIAN TEAM TO BUYER’S FACTORY FOR INSTALLATION AND TESTING THE WHOLE LINE.

If any interest to our machines, please kindly feel free to contact us:

Email: info@tongsanextruder.com info@wpcmachinery.com

Phone: 0086-13953226564

TEL:0086-532-82215318

Address: The West End And South Side Of Yangzhou Road,Jiaozhou City,Qingdao,China