Professional machine manufactuer flexible corrugated pipe machine

PVC HDPE single wall corrugated pipe machine

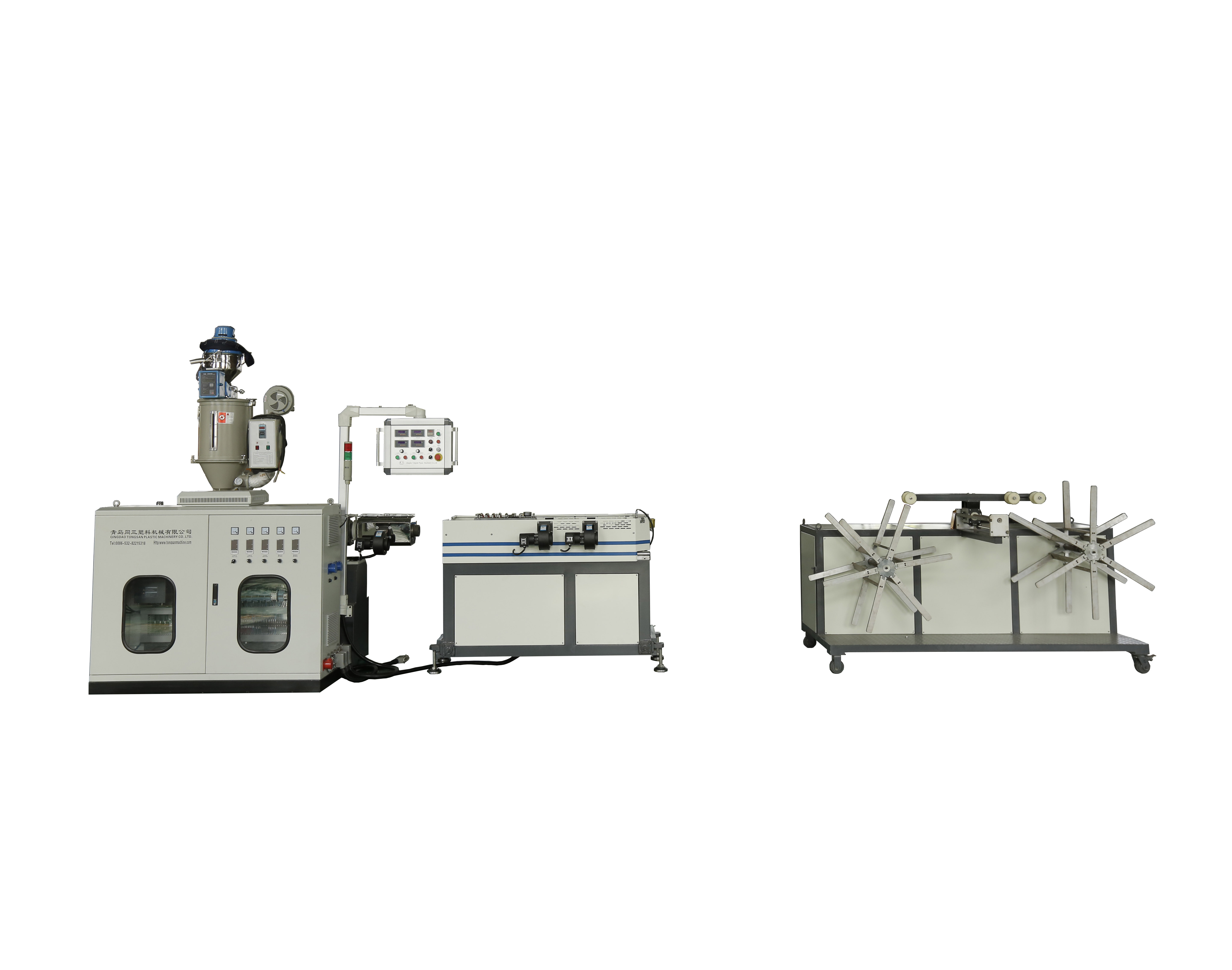

Single-wall corrugated pipe machine developed by our company adopts gears to run modules and templates so as to realize water circulating cooling and air cooling of the products, which ensures high-speed molding, even corrugation, smooth inner and outer pipe wall. These corrugated pipes are especially used in wires conduit pipe.It is mainly for the production of raw materials to PVC.PP.PE small diameter single wall corrugated pipe. Die by the corresponding forming a homogeneous single-wallcorrugated bellows products. Threading pipe for wire and cable, washing machinedrains, vacuum cleaners, ventilation pipe, prestressed concrete special tubes.

The Corrugated Pipe Machine Application

1. The PVC/PE single wall corrugated pipe machine can be used to produce small diameter PVC, PP and PE single wall corrugated pipes.

2. Corrugated pipes with smooth inside and outside surfaces, and even ripple are extruded once at a time.

The Final Product Application

Final product widely used in fields of auto wire, electric thread-passing pipes, circuit of machine tool, protective pipes of lamps and lanterns wire, tubes of air conditioner and washing machine, etc.

The Main Parts of Corrugated Pipe Machine

EXTRUDER PART

Vacuum feeding system,Drying loader,Various of screw and barrel

The advantages of plastic corrugated pipes

1. With both rigid and flexible: has sufficient mechanical properties, at the same time has excellent flexibility.

2. Compared with the plate pipe, corrugated pipe has lighter weight, save material, lower energy consumption, cheaper;

3. corrugated pipes with smooth inner wall can reduce the flow resistance of liquid in the pipe, improve the transmission capacity;

4. Good performance in resistance to chemical corrosion, can resist the effect of alkali in the soil.

5. Pipe with corrugation form can increase the load resistance of the pipe to the soil, at the same time, do not affect its flexibility,so that it can be laid on the uneven ground continuously.

6. Easily to connect and good in tightness . Easily handing, easily install, reduce the labor intensity, reduce working period.

7. Wide using temperature range, inflaming retarding, self-extinguish, safety in use.

8. safe insulation, is an ideal material for the electric wire conduit.

Our Service

Pre-sale services

1.Provide the free consultation of the machine

2.Provide the standard device and the flow chart

3.According to the clients' special requirement, offering the reasonable plan and free design helping to select the machine

4.Welcome to visit our factory or the domestic clients' factory.

1, WARRANTY TERMS:

1.1 WARRANTY PERIOD: 12 MONTHS, STARTING FROM THE FIRST DAY OF RUNNING MACHINES IN CUSTOMER’S WAREHOUSE

1.2 SELLER SHALL GRANT: SERVICES AND SPARE PARTS, FREE-OF-CHARGE SERVICE THROUGHOUT THE ENTIRE EQUIPMENT WARRANTY PERIOD.

1.3 LIFELONG SERVICE: THE SELLER SHOULD PROVIDE LIFELONG SERVICE FOR THE SOLD GOODS, THE BUYER PAY FOR NEEDED SPARE PARTS AFTER THE 12MONTHS WARRANTY TERMS.

2, DELIVERY CONDITIONS:

2.1 DELIVERY CONDITION: FOB QINGDAO PORT.

2.2 DELIVERY TERM: WITHIN 60 WORKING DAYS AFTER RECEIPT OF ADVANCED PAYMENT, THE SELLER SHOULD INFORM THE BUYER TO DO INSPECTION. THE SELLER SHOULD FINISH PACKING OF GOODS AND READY FOR SHIPMENT WITHIN 15 WORKING DAYS AFTER THE SELLER RECEIPT THE FULL PAYMENT.

2.3 SUPERVISION OF LOADING:THE SELLER SHOULD INFORM THE BUYER EXACTLING LOADING TIME, THE BUYER CAN ARRANGE FOR SUPERVISION OF LOADING.

3, INSPECTION:

WHEN THE MACHINE FINISHED, THE SELLER SHOULD INFORM THE BUYER TO DO INSPECTION BEFORE SHIPMENT, THE SELLER GUARANTY GOOD PERFORMANCE OF ALL THE SOLD GOODS.THE SELLER UNDERTAKE THE MATERIAL COST FOR THE MACHINE INSPECTION IN SELLER’S FACTORY. THE BUYER SHOULD COME TO SELLER’S FACTORY TO DO THE INSPECTION WORK, OR THE BUYER COULD ENTRUST ANY THIRD PARTT TO COME TO SELLER’S FACTORY TO DO THE INSPECTION WORK.

4, INSTALLATION AND EQUIPMENT COMMISSIONING:

IF THE BUYER REQUIRES, THE SELLER SHOULD SEND TECHNICIAN TEAM TO BUYER’S FACTORY FOR INSTALLATION AND TESTING THE WHOLE LINE.

If any interest to our machines, please kindly feel free to contact us:

Email: info@tongsanextruder.com info@wpcmachinery.com

Phone: 0086-13953226564

TEL:0086-532-82215318

Address: The West End And South Side Of Yangzhou Road,Jiaozhou City,Qingdao,China