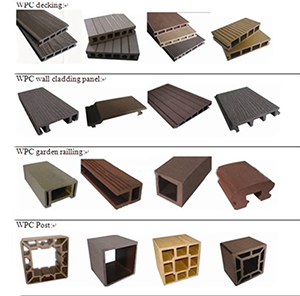

Product Application of Plastic Wood/PP/PE Profile Extrusion Production Line

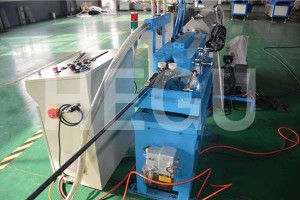

Combining advanced Canadian technology and the domestic practical situation, our company developed the SJMS series Plastic Wood/PP/PE Profile Extrusion Production Line.

The Plastic Wood/PP/PE Profile Extrusion Production Line is adopted specially designed screw, barrel,mold and unique WPC craft and formula initiated by our company.

The extruder can match with the auxiliary machines and moulds perfectly. The whole production line is of automatic control from the loading to the final discharging. The machines can also be manually adjusted

separately.

separately.

With the advantages of good plastics, low energy-consumption, high output,excellent performance, long endurance, etc. It can be equipped with relative auxiliary equipment,such as vacuum calibration platform, haul-off machine, cutting machine and material stacker.

It is mainly used for extruding outdoor decorative WPC profiles, such as gardening landscapes,outdoor landscapes, pallets, etc.

|

Item/Model |

SJMS65/132 |

SJMS51/105 |

SJ90*25 |

|

Extruder type |

Double screw |

Double screw |

Single screw |

|

Screw Diameter (mm) |

65 |

51 |

90 |

|

L/D Ratio |

22(25) |

22(25) |

25 |

|

Extrusion Capacity (kg/h) |

200-240 |

100-150 |

180-220 |

|

SPECIFICATIONS on Plastic Wood Profile Extrusion Production Line |

|||

|

Extruder |

Extruder model |

conical twin screws |

SJ-90*25 |

|

Extrusion capacity |

Spring auto-feeder |

180-220kg/hour |

|

|

Extrusion speed |

Base on size setting |

10-25m/hour |

|

|

Electrical control |

PLC control system |

SIEMENS S-700 |

10.4'' digital diagnose |

|

DC speed regular |

Connector |

Temperature meter |

|

|

EUROTHERM |

SIEMENS |

OMRON |

|

|

General information |

Machine weight |

10~15tons |

1 40' containers |

|

Machine overall dimension |

25m*3m*3m |

L*W*H |

|

|

Total install-power |

90~180kw |

380V 50Hz |

|

Main Features on WPC extruder machine wood plastic PE PP PVC composite deck roof floor

profile extrusion production line

1) Simple structure in linear type, easy in installation and maintation.

2) Adopting advanced world famous brand components in pneumatic parts, electric parts and operation parts.

3) High pressure oil temperature control the die extrusion.

4) Running in a high automatization and intellectualization, no pollution.

5) Apply a linker to connect with the air conveyor, which can directly inline with filling machine .

1, WARRANTY TERMS:

1.1 WARRANTY PERIOD: 12 MONTHS, STARTING FROM THE FIRST DAY OF RUNNING MACHINES IN CUSTOMER’S WAREHOUSE

1.2 SELLER SHALL GRANT: SERVICES AND SPARE PARTS, FREE-OF-CHARGE SERVICE THROUGHOUT THE ENTIRE EQUIPMENT WARRANTY PERIOD.

1.3 LIFELONG SERVICE: THE SELLER SHOULD PROVIDE LIFELONG SERVICE FOR THE SOLD GOODS, THE BUYER PAY FOR NEEDED SPARE PARTS AFTER THE 12MONTHS WARRANTY TERMS.

2, DELIVERY CONDITIONS:

2.1 DELIVERY CONDITION: FOB QINGDAO PORT.

2.2 DELIVERY TERM: WITHIN 60 WORKING DAYS AFTER RECEIPT OF ADVANCED PAYMENT, THE SELLER SHOULD INFORM THE BUYER TO DO INSPECTION. THE SELLER SHOULD FINISH PACKING OF GOODS AND READY FOR SHIPMENT WITHIN 15 WORKING DAYS AFTER THE SELLER RECEIPT THE FULL PAYMENT.

2.3 SUPERVISION OF LOADING:THE SELLER SHOULD INFORM THE BUYER EXACTLING LOADING TIME, THE BUYER CAN ARRANGE FOR SUPERVISION OF LOADING.

3, INSPECTION:

WHEN THE MACHINE FINISHED, THE SELLER SHOULD INFORM THE BUYER TO DO INSPECTION BEFORE SHIPMENT, THE SELLER GUARANTY GOOD PERFORMANCE OF ALL THE SOLD GOODS.THE SELLER UNDERTAKE THE MATERIAL COST FOR THE MACHINE INSPECTION IN SELLER’S FACTORY. THE BUYER SHOULD COME TO SELLER’S FACTORY TO DO THE INSPECTION WORK, OR THE BUYER COULD ENTRUST ANY THIRD PARTT TO COME TO SELLER’S FACTORY TO DO THE INSPECTION WORK.

4, INSTALLATION AND EQUIPMENT COMMISSIONING:

IF THE BUYER REQUIRES, THE SELLER SHOULD SEND TECHNICIAN TEAM TO BUYER’S FACTORY FOR INSTALLATION AND TESTING THE WHOLE LINE.

If any interest to our machines, please kindly feel free to contact us:

Email: info@tongsanextruder.com info@wpcmachinery.com

Phone: 0086-13953226564

TEL:0086-532-82215318

Address: The West End And South Side Of Yangzhou Road,Jiaozhou City,Qingdao,China

-

Plastic recycling machine PVC hot cut granulat...

-

Reasonable price for Pvc Pipe Making Machine /f...

-

Wholesale Discount Plastic Flexible Pvc Pp Pe P...

-

Corrugated pipe machine PP wrapping steel wire...

-

IOS Certificate Best Choice Plastic Corrugated ...

-

2019 wholesale price Pvc 70/75 Plastic Sheet Pl...