We believe in: Innovation is our soul and spirit. Good quality is our life. Shopper need to have is our God for Factory Supply Pvc Wood Plastic Composite Door Panel Making Machine /wpc Profile Production Line, You may uncover the lowest price here. Also you are going to get good quality products and solutions and fantastic service here! You should will not be reluctant to get hold of us!

We believe in: Innovation is our soul and spirit. Good quality is our life. Shopper need to have is our God for Household Plastic Products Making Machine, Machines For Pvc Door Panels, Pvc Door Board Panel Production Line, We have now top engineers in these industries and an efficient team in the research. What is more, we've our own archives mouths and markets in China at low cost. Therefore, we can meet different inquiries from different clients. Be sure to find our website to check more information from our solutions.

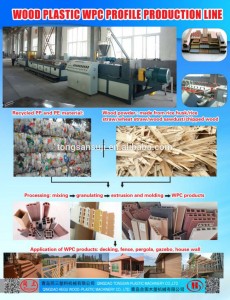

Description of WPC products.

1, New product: The wood-plastic is a new kind of synthetic material through the process of mixing,exruding,calibrating,hualing off and cutting,

2, Material: uses PVC,PP,PE resin or recycled plastic and plant fibre ( wood powder,chaff,straw etc.) as raw material.

3, Advantages: This kind of wood-plastic are not only very similar with natural wood in appearance and feel, but also have the same characteristics as wood of excisable, planeable,sawable, unmatched grip,low bibulous rate, good moisture resistance, mothproof,mildew resistance,good resistance to acid and alkali,anti-corrosion, and it has the feature of fire resistance. The products are non-toxic,non-polluting,environment-friendly and save-energied, without formaldehyde, benzene and ammonia and other harmful substances.

4, Application: The wood-plastic products are widely used in outdoor floor, close to water construction,balcony,landscape architecture,chairs and benches, fences, interior doors and windows, furniture, etc.

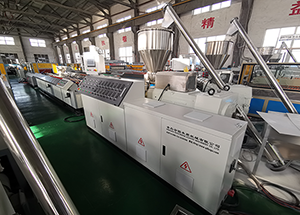

WPC profile machinery/ WPC machine extruder/wood plastic composite machine

WPC wood plastic composition machine including mixer,

wood miller, WPC granulator, WPC profile extrusion line,

sanding machine, brushing machine, embossing machine,

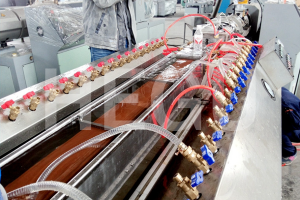

WPC conical double screw extruders,

WPC decking production line machine.

WPC machine/wood plastic composite machine/wpc wall panel extrusion line

WPC production line with conical double screw extruder

wood plastic composite machine/Plastic wood WPC Machine

Production flow for wood plastic WPC decking machine

1, Preparing the material:

wood powder material: 80-100mesh wood powder, it can be made from wood sawdust, rice husk, rice straw, wheat husk and straw, cotton staw and agriculture wastage. machine need is wood crushing and pulverizer machine

plastic material: recycled PP/PE plastic after washing and crushing into flakes. machine need is plastic washing and crushing line.

2, WPC material mixing and granulating

Mixing: put all the material into the mixing machine, such as PP/PE recycled flakes, wood powder, chemical additives

Granulating: it is important to use a high quality granulating machine to make WPC granules, moisture exhuasting system is necessary for granulating process.

3, WPC products extrusion-molding-surface treatment

Extrusion and molding:Our conical double screw extruder is specially designed for high quality WPC products extrusion, it can make WPC material fully mixed and melted and uniform,equip with good deisgned mold and calibration, online cutting device, our Wood plastic WPC profile machine can make good WPC products, such as decking prodfiles, garden profiles, chair profiles, pergoza profiles, railing system profiles.

Surface treatment: sanding, brushing and embossing process can make the WPC products with nature wooden grain which is good accepted by customers.

A mix of natural wood and plastic fiber forms wood-plastic composites. These help in reducing the overall weight of a vehicle, and in turn, it enhances its fuel efficiency. Wood plastic composites are a low-priced and eco-friendly substitute to plastic and steel components in construction applications. Hence, their demand is constantly growing in the market.

The wood-plastic composites market is segmented by types: Polyethylene (PE), Polypropylene (PP), Polyvinyl Chloride (PVC) and others. Polyethylene based wood plastic composites dominate the industry. The building & construction products segment is regarded to be the largest consumer of Polyethylene and Polyvinyl Chloride wood-plastic composites. The automotive components segment comes in next where wood-plastic composites are used in the making of lightweight automotive components

Based on their application, this market has been segmented into building & construction products, decking, fencing, industrial & consumer goods, automotive components, and others. Among these, the building and construction segment appeared as the largest in the global wood-plastic composites market.

1, WARRANTY TERMS:

1.1 WARRANTY PERIOD: 12 MONTHS, STARTING FROM THE FIRST DAY OF RUNNING MACHINES IN CUSTOMER’S WAREHOUSE

1.2 SELLER SHALL GRANT: SERVICES AND SPARE PARTS, FREE-OF-CHARGE SERVICE THROUGHOUT THE ENTIRE EQUIPMENT WARRANTY PERIOD.

1.3 LIFELONG SERVICE: THE SELLER SHOULD PROVIDE LIFELONG SERVICE FOR THE SOLD GOODS, THE BUYER PAY FOR NEEDED SPARE PARTS AFTER THE 12MONTHS WARRANTY TERMS.

2, DELIVERY CONDITIONS:

2.1 DELIVERY CONDITION: FOB QINGDAO PORT.

2.2 DELIVERY TERM: WITHIN 60 WORKING DAYS AFTER RECEIPT OF ADVANCED PAYMENT, THE SELLER SHOULD INFORM THE BUYER TO DO INSPECTION. THE SELLER SHOULD FINISH PACKING OF GOODS AND READY FOR SHIPMENT WITHIN 15 WORKING DAYS AFTER THE SELLER RECEIPT THE FULL PAYMENT.

2.3 SUPERVISION OF LOADING:THE SELLER SHOULD INFORM THE BUYER EXACTLING LOADING TIME, THE BUYER CAN ARRANGE FOR SUPERVISION OF LOADING.

3, INSPECTION:

WHEN THE MACHINE FINISHED, THE SELLER SHOULD INFORM THE BUYER TO DO INSPECTION BEFORE SHIPMENT, THE SELLER GUARANTY GOOD PERFORMANCE OF ALL THE SOLD GOODS.THE SELLER UNDERTAKE THE MATERIAL COST FOR THE MACHINE INSPECTION IN SELLER’S FACTORY. THE BUYER SHOULD COME TO SELLER’S FACTORY TO DO THE INSPECTION WORK, OR THE BUYER COULD ENTRUST ANY THIRD PARTT TO COME TO SELLER’S FACTORY TO DO THE INSPECTION WORK.

4, INSTALLATION AND EQUIPMENT COMMISSIONING:

IF THE BUYER REQUIRES, THE SELLER SHOULD SEND TECHNICIAN TEAM TO BUYER’S FACTORY FOR INSTALLATION AND TESTING THE WHOLE LINE.

If any interest to our machines, please kindly feel free to contact us:

Email: info@tongsanextruder.com info@wpcmachinery.com

Phone: 0086-13953226564

TEL:0086-532-82215318

Address: The West End And South Side Of Yangzhou Road,Jiaozhou City,Qingdao,China

-

Factory source 2018 Pp Pe Glazed Corrugated Roo...

-

2019 China New Design China Plastic Sylphon Bel...

-

Lowest Price for China WPC Extrusion Machine Wo...

-

2019 China New Design China PE PP PVC Corrugate...

-

Good quality Cold steel three layer roll formin...

-

Leading Manufacturer for China Plastic HDPE Dou...